Home > Products > HP Graphite Electrode > High Power Grade HP450mm Graphite Electrode Foundry Graphite Electrode

According to the design characteristics of the electric arc furnace, the electrode suitable for the production of the EAF should be selected reasonably, and the product with the best cost performance should be selected. It is very necessary to carefully select the electrode suitable for each furnace. The special properties of the steelmaking furnace, the feeding method, the maximum current intensity, the length of the electrode column under the holder, the distance between the side wall of the furnace and the electrode circumference, etc. All the factors must be considered when choosing an electrode for an EAF.

Products Describe

Precautions for the use of graphite electrodes:

① For wet graphite electrodes, dry them before use.

② Remove the foam protective cap from the spare graphite electrode hole and check whether the inner thread of the electrode hole is complete.

③ Clean the surface of the spare graphite electrode and the inner thread of the hole with compressed air free of oil and water, and avoid cleaning with steel wire balls, metal brushes, and emery cloths.

④ Carefully screw the joint into the electrode hole at one end of the spare graphite electrode (it is not recommended to put the joint directly into the electrode removed from the furnace) without colliding with the thread.

⑤ Screw the electrode sling (a graphite sling is recommended) into the electrode hole at the other end of the spare electrode.

⑥ When lifting the electrode, place a soft object under the end of the spare electrode installation joint to prevent the ground from damaging the joint. Insert the hook into the lifting ring of the sling and lift it up. Lift the electrode smoothly to prevent it from falling off from the B end or colliding with other fixtures.

⑦ Hang the spare electrode above the electrode to be connected, and then slowly drop it after aligning with the electrode hole; rotate the spare electrode so that the spiral hook and the electrode can rotate and fall together; when the end faces of the two electrodes are 10–20 mm apart, clean the electrode with compressed air. When the electrode is fully lowered at the end, do not use too much force; otherwise, the thread of the electrode hole and the connector will be damaged due to a violent collision.

⑧ Use a torque wrench to twist the spare electrode until the end faces of the two electrodes are in close contact (the correct connection gap between the electrode and the connector is less than 0.05mm).

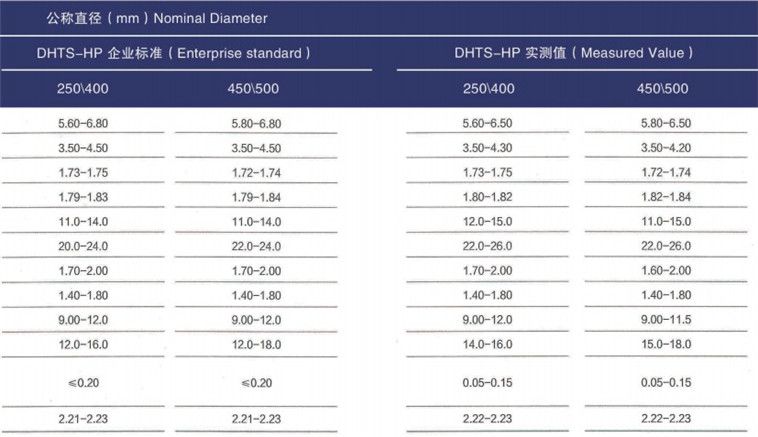

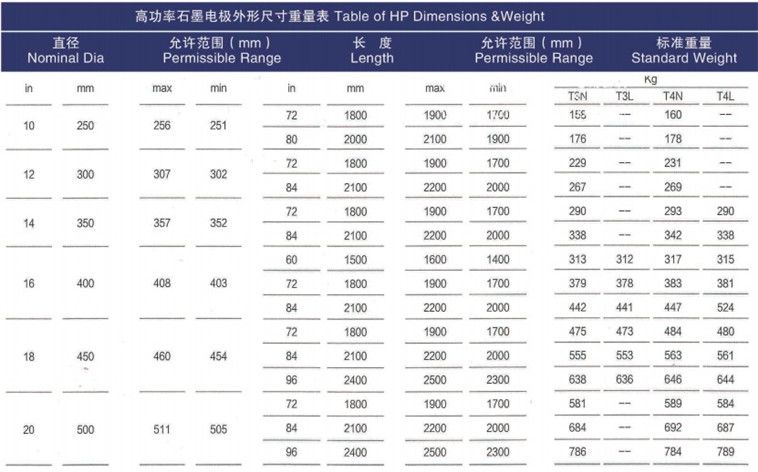

Product Parameters

Packing and Shipping

FAQ

1. When can i get the price?

A: We usually quote within 24 hours after getting your detailed requirements, like size, quantity etc. If it is an urgent order, we will be grateful for your prompt calling.

2. What is the delivery time of bulk products?

A: Delivery time depends on quantity, about 7-12 days. For graphite products, it takes approximately 15-20 working days to apply for a dual-use goods license.

3. What are the terms of payment?

A: We accept T/T 30% as down payment and the balance before delivery.

4. Product packaging?

A: We are packed in bulk ship or in ton bag or placing in container or according to your requirements.

Inquire Basket (0)