The process and corresponding time for the production of a batch of ultra-high-power or high-power graphite electrodes are as follows: electrode pressure type (3 days)——roasting (25 days)——impregnation (4 days)——re-roasting (15 days)——Graphitization (10 days)——Machining & quality inspection (2 days)——Finished product packaging and delivery (1 day), that is, from feeding to product shipment, the fastest cycle of non-stop production is also 60 days. However, since the production of electrode nipples requires more two-immersion and three-baking treatment than electrodes, the fastest production cycle is 90 days.

Products Describe

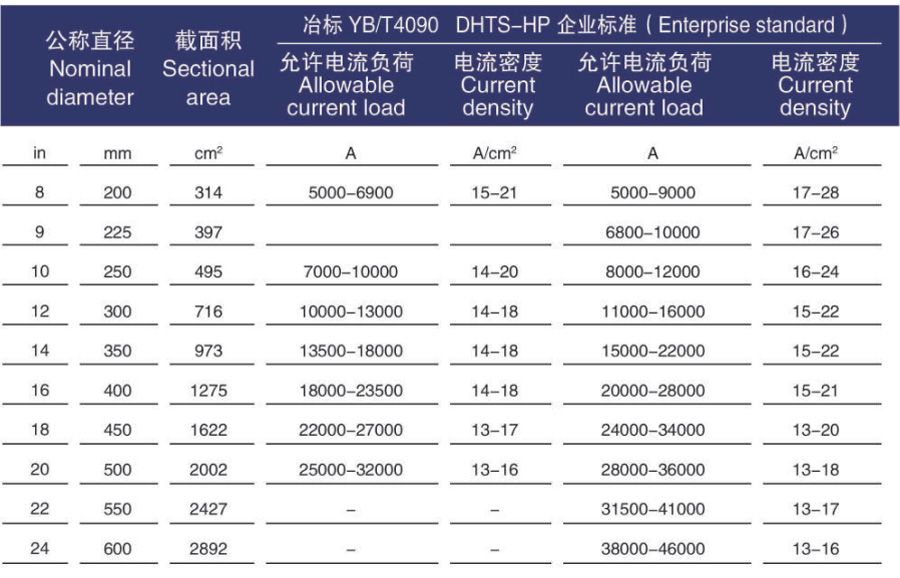

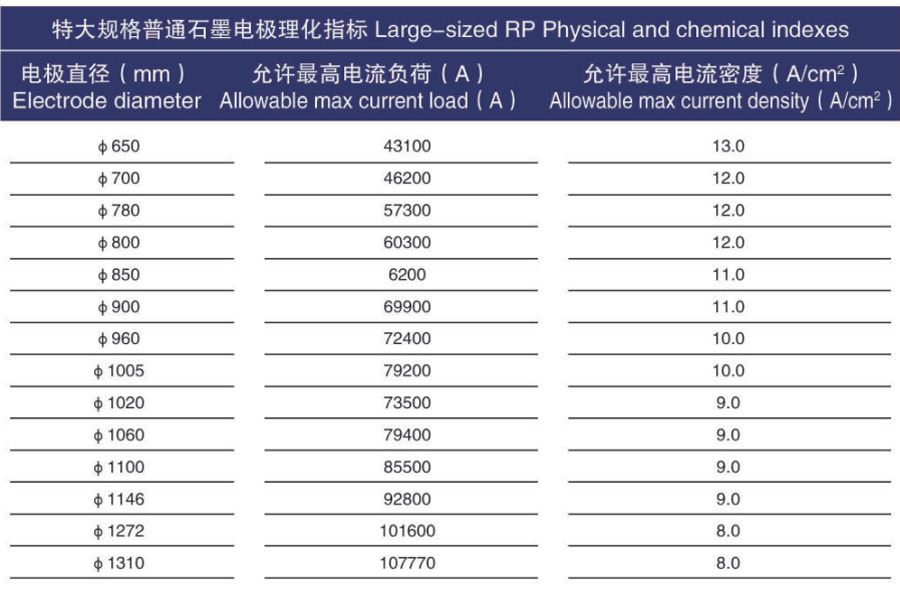

Ordinary power graphite electrodes are allowed to use graphite electrodes with a current density lower than 17 A/cm2 and are mainly used in ordinary power electric furnaces for steelmaking, silicon smelting, yellow phosphorus smelting, etc.

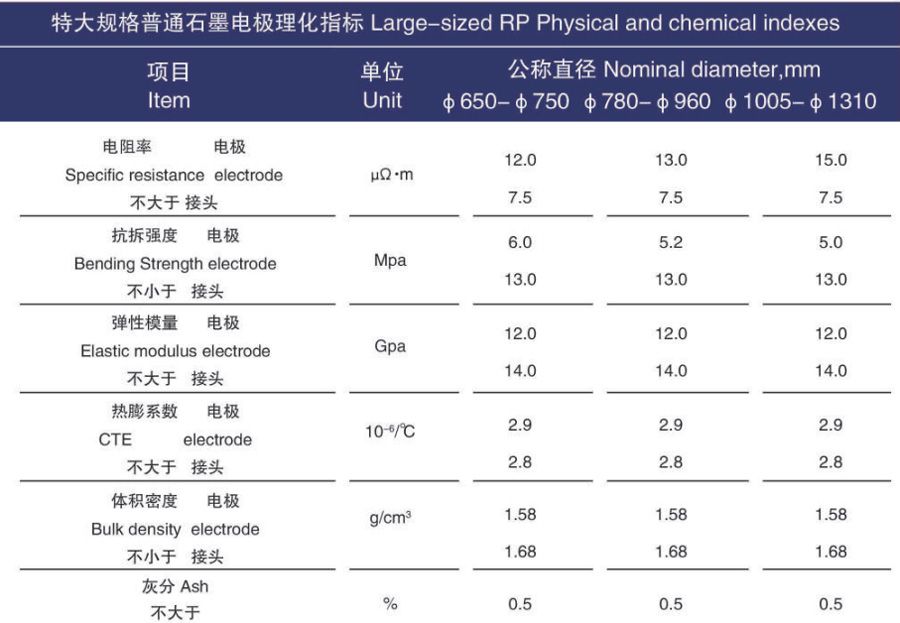

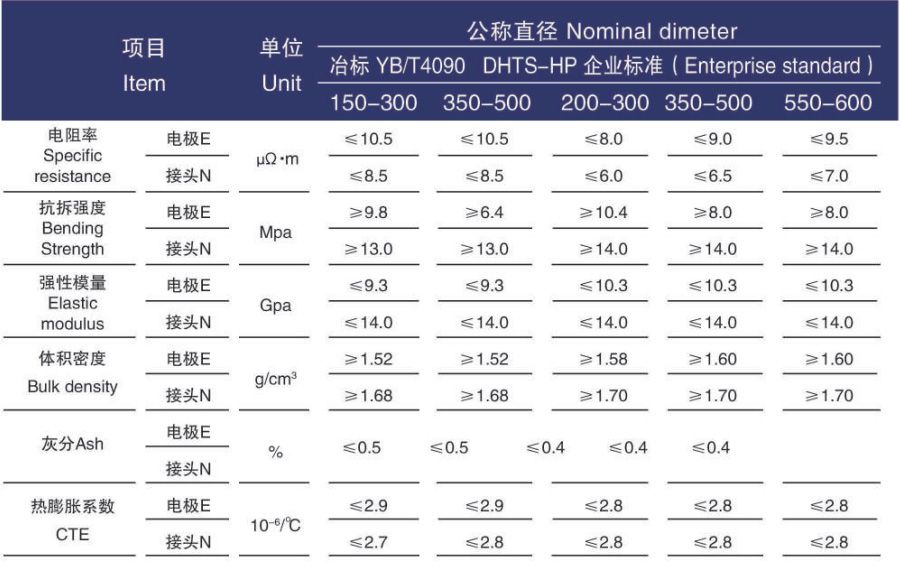

The thermal expansion coefficient of graphite electrodes is a very important thermodynamic parameter. The lower the value, the stronger the thermal stability of the product. The higher the oxidation resistance, the less the fracture and the lower the consumption in use. The main ways to reduce the thermal expansion coefficient are: Use good-quality raw materials, use a formula with a larger particle size, or increase the amount of large particles (but it will reduce the density and strength of the product).

Ash refers to the content of solid elements other than carbon and graphite in the product. The ash content of graphite electrodes is mainly affected by the ash content of the raw materials used. The ash content of petroleum coke and needle coke is low, so the ash content of graphite electrodes generally does not exceed 0.5%, and the ash content within 1% has no obvious impact on steelmaking, but the impurity elements in the ash will reduce the oxidation resistance of the electrode.

The thermal shock resistance factor is a parameter that characterizes thermal shock resistance performance. The thermal shock resistance performance is a characteristic of the material itself. It expresses a performance that withstands rapid cooling and heating. The performance of anti-fragmentation is a very important and comprehensive factor affecting the use of electrodes.

Product Parameters

Packing and Shipping

FAQ

1. Are you trading company or factory?

A: We have the most advanced machine and about 80 employee in our 15000m2 workshop.

2. How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

3. How to determine the grade of graphite electrode?

A: Please send us an inquiry and our sales manager will confirm the details and prices for you.

Customers will be asked to provide EAF parameters and electrode specifications and dimensions

4. What's the lead time?

A: 2-3 weeks after receiving the deposit.

Inquire Basket (0)