How to identify the high quality of petroleum coke using different grades

Petroleum coke's 3A and 2B are the most commonly used quality grading codes in the industry. The core grading is based on "sulfur content + structural morphology," directly determining its application and price. Simply put: the earlier the letter and the smaller the number, the better the quality.

I. Core Grading Logic (Industry-widely accepted standard, sulfur content is the primary consideration)

The grading focuses on two key factors: sulfur content (core indicator) + true density/pore structure (auxiliary). The letters A/B/C correspond to high/low sulfur content, while the numbers 1/2/3 correspond to good/bad structural quality. The rules are simple:

• Letters: A > B > C (Sulfur content increases sequentially, with grade A having the lowest sulfur content and the best quality)

• Numbers: 1 > 2 > 3 (Structure becomes increasingly porous, with grade 1 having the densest structure and the best performance)

II. Specific Meanings of 3A and 2B (Most Practical Interpretation)

1. 3A Petroleum Coke (Mid-to-High-End Grade, Cost-Effective Choice)

• Core Indicators: Sulfur content ≈ 0.5%~1.0%, True density ≈ 2.08~2.12 g/cm³, Medium-Dense Structure, Few Impurities

• Core Uses: Mainly used in prebaked anodes (core raw material for electrolytic aluminum), mid-to-high-end graphite electrode auxiliary materials, and can also be used to make high-power carbon blocks. It is one of the most widely used grades in the carbon industry.

• Characteristics: Low sulfur, low ash content, balanced performance, more affordable than 1A/2A, and more affordable than B-grade coke. High premium

2. 2B Petroleum Coke (Mid-to-low end, economical)

• Key indicators: Sulfur content ≈ 1.0%~2.0%, true density slightly lower than 3A, looser structure, higher impurity content than Grade A coke

• Core uses: Primarily used in ordinary graphite electrodes, carbon electrodes, carbon bricks, and negative electrode materials (low end). Also suitable as fuel coke (industrial boilers, cement kilns). Applications lean towards "non-high-end carbon + fuel"

• Characteristics: Medium sulfur content, price 10%~30% lower than Grade A coke (fluctuates with market), prioritizes cost-effectiveness, suitable for scenarios with less stringent sulfur requirements.

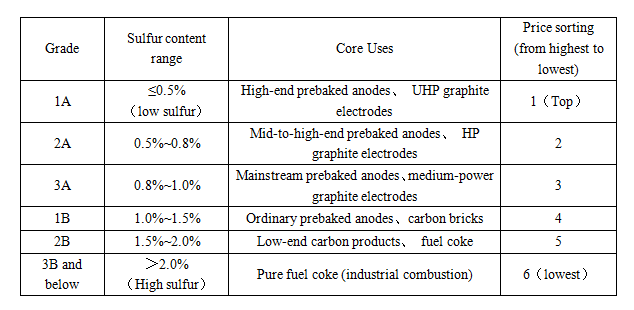

III. Supplement: Comparison of Common Grades (Distinguish Good from Bad at a Glance)

IV. Key Reminders (Avoiding Pitfalls)

1. There is no unified national standard for grading, but there is a consensus in the industry: Different refineries (such as Sinopec, PetroChina, and independent refineries) may have slight variations in their specifications, but the logic of "A is better than B, and the lower the number, the better" applies across the industry. Contracts must specify the exact values for sulfur content, ash content, and true density; do not rely solely on grade codes.

2. Application determines grade selection: For electrolytic aluminum anodes/high-end graphite, prioritize grade A (1A~3A); for low-end carbon products/fuels, choose grade B and below. Choosing the wrong grade will lead to substandard product performance or wasted costs.

3. Price is linked to sulfur content: For every 0.1% increase in sulfur content, the price typically drops by 50~200 yuan/ton (following overall petroleum coke market fluctuations). The price difference between 3A and 2B is one of the core considerations in carbon procurement.