UHP graphite electrodes are mainly made of high-quality needle coke as raw materials, and implement the national industry standard "YBT4090-2000 UHP Graphite Electrode Standard". Let us introduce the composition and national standards of UHP graphite electrodes and the difference between UHP graphite electrodes and HP graphite electrodes.

①.What are the components of UHP graphite electrodes?

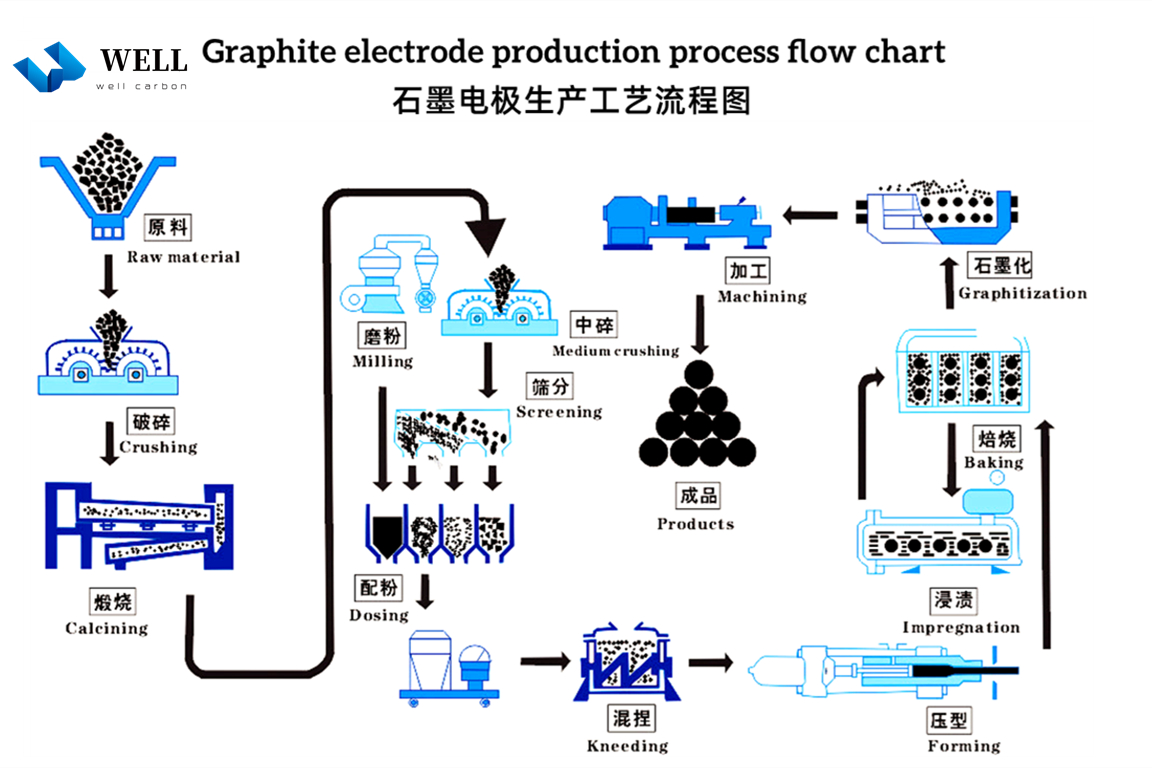

The UHP graphite electrode is mainly made of high-quality needle coke as raw material, and coal tar pitch is added as a binder. It is refined through the processes of crushing, screening, batching, kneading, pressing, roasting, high-pressure impregnation, secondary roasting, and mechanical processing.

Graphite electrode grade classification indicators are based on values such as resistivity, flexural strength, elastic modulus, bulk density and thermal expansion coefficient.

②.UHP graphite electrode features:

1. Good high temperature resistance, it will not melt very early in the steelmaking furnace due to high temperature;

2. Good stability, no deformation during the electrification process, stable chemical properties, and will not react with various raw materials mixed in the smelting furnace;

3. Good electrical conductivity, less power consumption, good electrical conductivity and thermal conductivity, saving steelmaking electricity consumption;

4. The graphitization heat treatment of the UHP graphite electrode should be carried out in the inner string graphitization furnace, and the graphitization temperature is as high as 2800 ~ 3000 ° C, so the resistivity is lower, allowing a larger current density to pass through, and the thermal expansion coefficient is smaller. Has excellent thermal shock resistance.

③. UHP graphite electrodes implement national standards

The UHP graphite electrode currently implements the national industry standard number: YBT4090-2000 "UHP graphite electrode standard". The UHP graphite electrode standard specifies the shape, size and allowable deviation value of the electrode, parameter indicators, allowable current load value, test specifications, storage, transportation and quality certificates.

The production process flow of UHP graphite electrode is shown in the following figure:

④.The difference between UHP graphite electrodes and HP graphite electrodes

1. RP graphite electrodes are used in ordinary steelmaking electric furnaces, and ordinary petroleum coke can be used as raw material. In the production process, the graphitization temperature is low, the resistivity is high, the thermal expansion coefficient is large, and the bending resistance is slightly poor, so the allowable current load is small.

2. HP graphite electrodes are used in electric arc furnaces for refining steel, using HP petroleum coke (or low-grade needle coke) as raw materials. After the impregnation treatment, the resistivity is low and the allowable current load is increased, so the physical properties are higher than ordinary graphite electrodes.

3. The UHP graphite electrode is used for conducting electricity in high-precision steel-making electric arc furnaces, and high-quality imported needle coke is used as the raw material. After three times of impregnation and four calcinations, the graphite electrode has a lower resistivity, a smaller expansion coefficient, a larger allowable current load and a strong physical bending resistance.